Re: Stewart Systems covering process discussion

Ok..just ran across this again, and I'd planned on putting it in this thread. I'll also put it in the "tape shrinking" thread if I can find it.

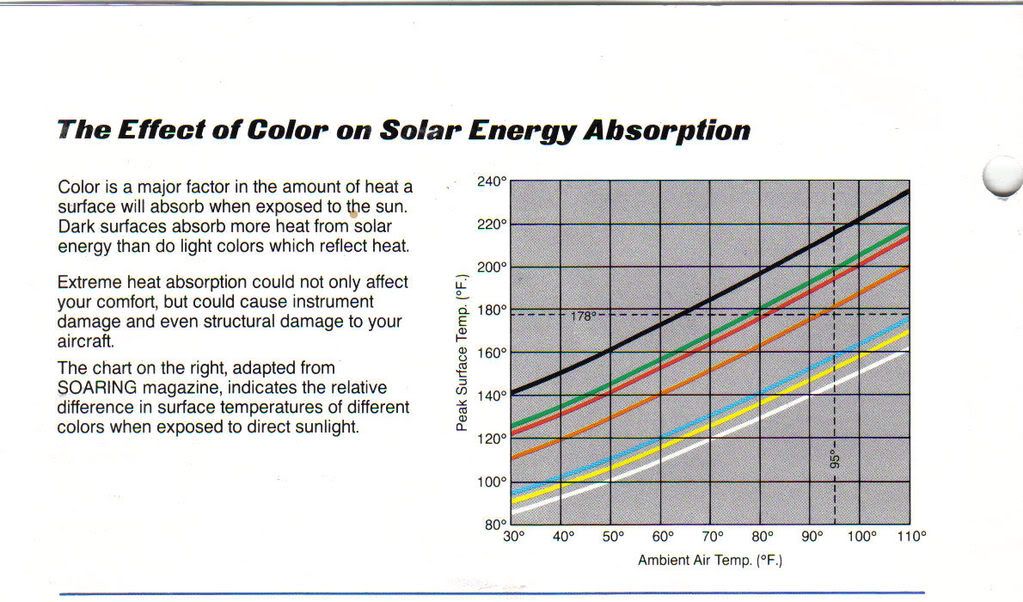

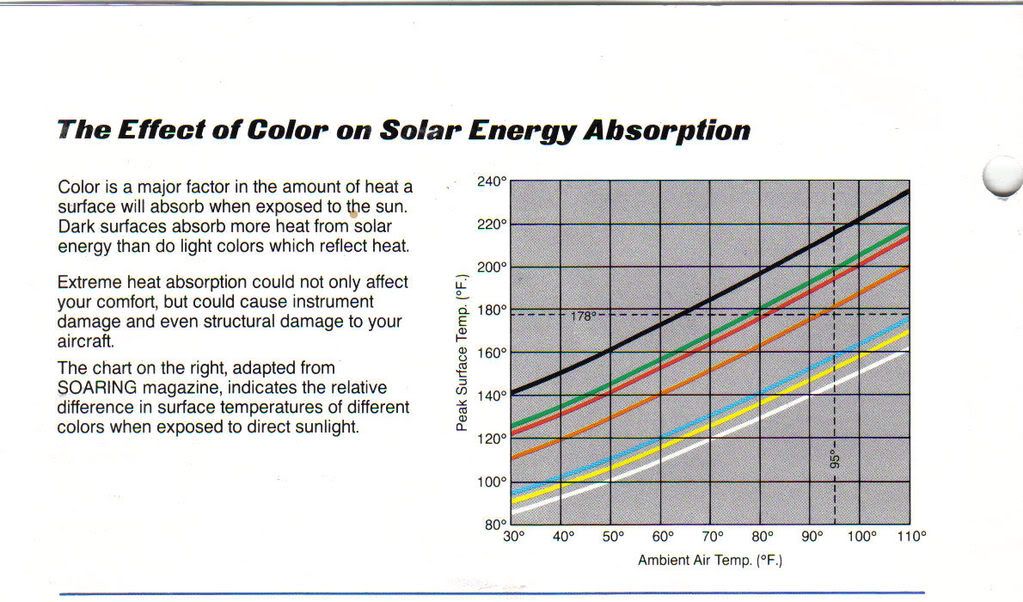

Here's a graph that Dupont put out, showing the effect of color on temperature.

Ok..just ran across this again, and I'd planned on putting it in this thread. I'll also put it in the "tape shrinking" thread if I can find it.

Here's a graph that Dupont put out, showing the effect of color on temperature.

Comment